ESP32 ADC

Introduction to ADC functions, and Joystick, Thermistor, Photoresistor, Gas sensors (MQ-2, MQ-3, MQ-135), eNose.

ADC (Analog Digital Converter)

Vin is input voltage for ADC to sample

Vref is reference voltage for ADC to compare with Vin

3-bit ADC example:

12-bit ADC : output is a 12-bit binary code, so its value = 0 ~ 4095

ADC architecture

Direct-Conversion ADC

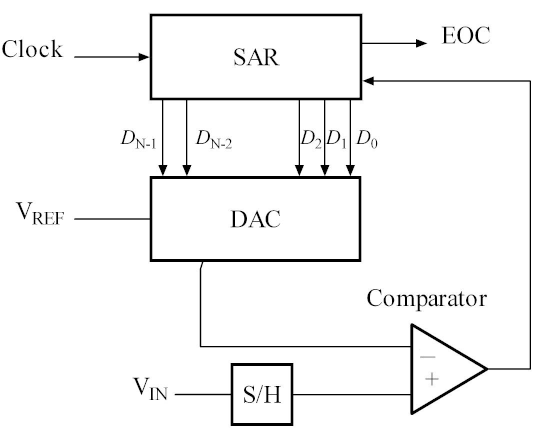

Successive-Approximation ADC

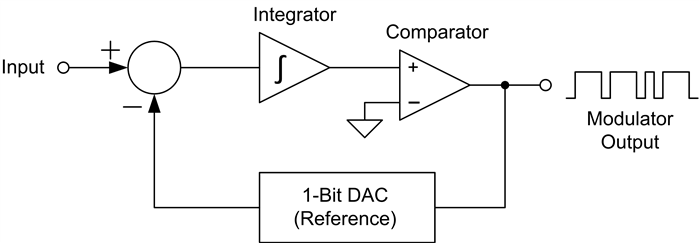

Sigma-Delta ADC

ESP32 ADC

Analog Input Tutorial

Vout = Vin * R2 / (R1+R2)

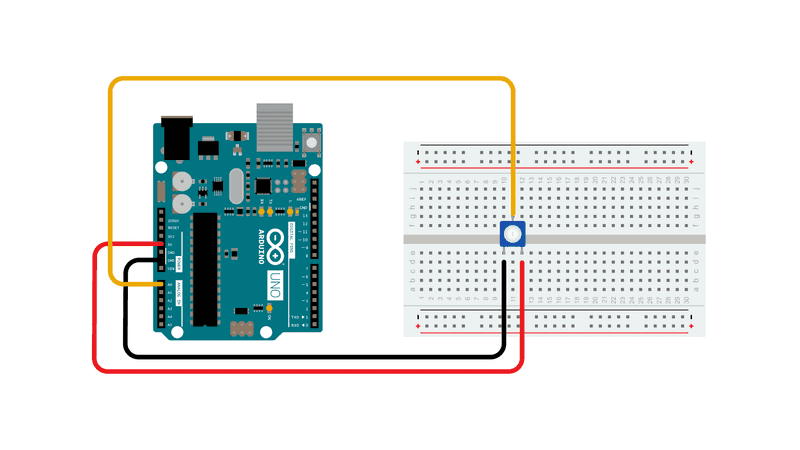

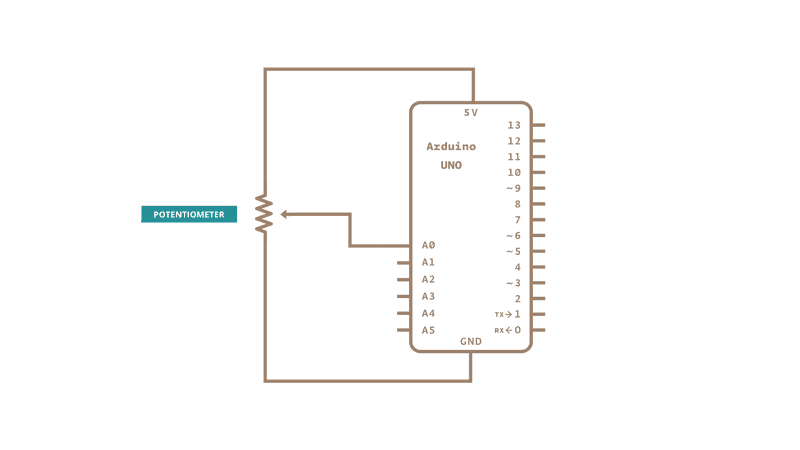

With a potentiometer

|

|

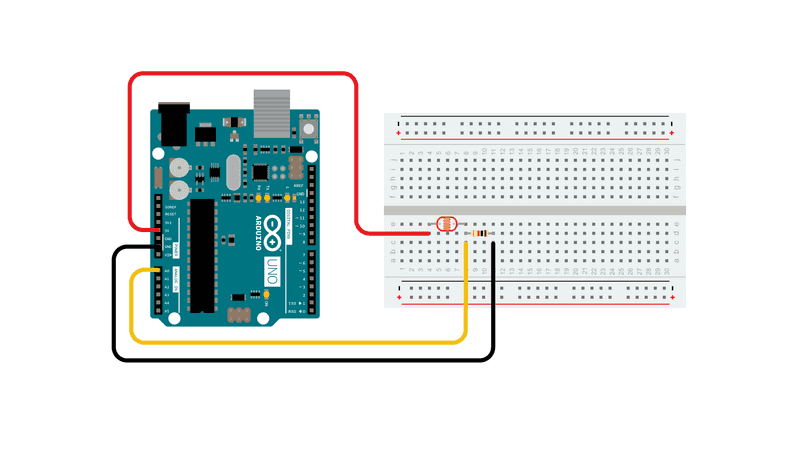

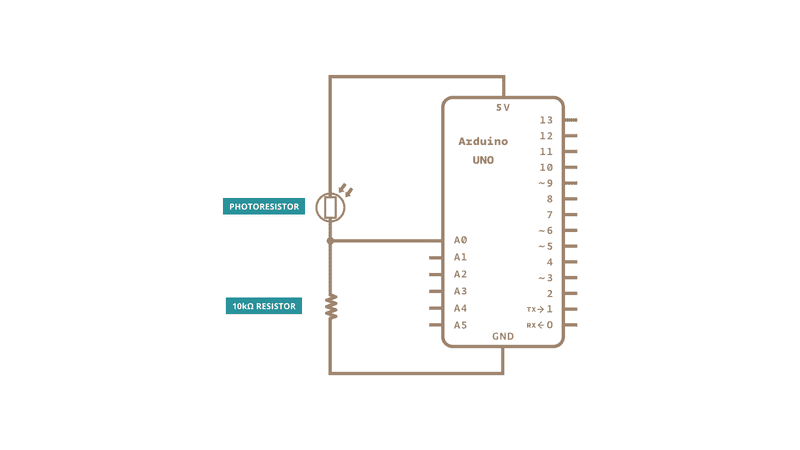

With a photoresistor

|

|

NodeMCU-32S pinout

Sketch> ESP32> ESP32_ADC

- Connect NodeMCU-32S with a NTC-Thermistor and a 10K ohm to GND

- Download ESP32_ADC.ino

to ~/Documents/Arduino/examples/

- Verify, then Tools>Serial Monitor>

Sketch> ESP32 > ESP32_ADC_Joystick

Examples> 03.Analog>

-

AnalogInOutSerial - Read an analog input pin, map the result, and then use that data to dim or brighten an LED.

-

AnalogWriteMega - Fade 12 LEDs on and off, one by one, using an Arduino Mega board.

-

Calibration - Define a maximum and minimum for expected analog sensor values.

-

Fading - Use an analog output (PWM pin) to fade an LED.

-

Smoothing - Smooth multiple readings of an analog input.

Examples> 03.Analog> AnalogInput

- Connect NodeMCU-32S with a NTC-Thermistor and a 10K ohm pulldown.

- AnalogInput.ino read sensor value as delay to turn LED on & off

- To show sensorValue

- setup() to add `Serial.begin(9600);

- loop() to add

Serial.println(sensorValue);

- Verify, then Tools>Serial Monitor>

Examples> 03.Analog> AnalogInOutSerial

-

Connect NodeMCU-32S with a NTC Thermistor and a 10K ohm pulldown.

-

Modify AnalogInOutSerial.ino

- analogOutPin = 2

- replace analogWrite to ledcWrite (for ESP32 PWM)

const byte ledPin = 2; // for ESP32 built-in LED

// setting PWM properties

const int freq = 5000;

const int ledChannel = 0;

const int resolution = 10; //Resolution 8, 10, 12, 15

ledcSetup(ledChannel, freq, resolution); // configure LED PWM functionalitites

ledcAttachPin(analogOutPin, ledChannel); // attach the channel to the GPIO2 to be controlled

ledcWrite(ledChannel, 102); //PWM Value varries from 0 to 1023

-

Compile

-

Verify, then Tools>Serial Monitor>

NTC Thermistor

Negative Temperature Coefficient = Rising Temperature will decrease Resistance

NTC thermistors can also be characterised with the B (or β) parameter equation,

where the temperatures and the B parameter are in kelvins, and R0 is the resistance at temperature T0 (25 °C = 298.15 K).

Solving for R yields

取log

log(R) = log(R0) + B * (1/T – 1/T0)

1/T = 1/T0 + (log(R) – log(R0)) / B

T = 1 / (1/T0 + (log(R) – log(R0)) /B)

[Homework] Thermistor.ino

- write above formula in C++

- create Thermistor.ino with the following codes

Read ADC (get ADCvalue)

int16_t ADCvalue;

void setup(){

Serial.begin(9600);

}

void loop() {

ADCvalue = analogRead(A0);

Thermistor(ADCvalue);

}

Read Thermistor (use ADCvalue to calculate R & T)

void Thermistor(int16_t ADCvalue)

{

double T, Temp;

double T0 = 301.15; // 273.15 + 28 (room temperature) 室溫換成絕對溫度

double lnR;

int16_t R; // Thermistor resistence

int16_t R0 = 8805; // calibrated by reading R at room temperature (=28 degree Celsius )

int16_t B = 3950;

int16_t Pullup = 9930; // 10K ohm

// R / (Pullup + R) = adc / 4096

R = (Pullup * ADCvalue) / (4096 - ADCvalue);

// B = (log(R) - log(R0)) / (1/T - 1/T0)

T = 1 / (1/T0 + (log(R)-log(R0)) / B );

Temp = T - 273.15;

Serial.println(Temp);

}

[Homework] Thermistor_accuracy.ino

- Create Thermistor_accuracy.ino

- Verify on NodeMCU-32S and, compare it to Thermistor.ino output

From Sketch/ESP32_ADC.ino

V = ReadVoltage(A0); //accuracy improved

double ReadVoltage(byte pin){

double reading = analogRead(pin); // Reference voltage is 3v3 so maximum reading is 3v3 = 4095 in range 0 to 4095

if(reading < 1 || reading > 4095) return 0;

// return -0.000000000009824 * pow(reading,3) + 0.000000016557283 * pow(reading,2) + 0.000854596860691 * reading + 0.065440348345433;

return -0.000000000000016 * pow(reading,4) + 0.000000000118171 * pow(reading,3)- 0.000000301211691 * pow(reading,2)+ 0.001109019271794 * reading + 0.034143524634089;

} // Added an improved polynomial, use either, comment out as required

Then,

V / 5 = R / (10K + R)

V = 5 * R / (10000+R)

V * (10000 + R) = 5 * R

10000 * V = 5 * R - V * R

10000 * V = (5 - V) * R

R = 10000 * V / (5-V)

V = ReadVoltage(A0); // ADC accuracy improved for ESP32

R = 9990 * V / (5 - V); // assuming 9990 is the measured resistance of 10K resistor by a multi-meter.

T = 1 / (1/T0 + (log(R)-log(R0)) / B ); // R0=8805 measured in room tempature at 28 celsius degree.

Temp = T - 273.15;

Serial.println(Temp);

Photoresistor

LDR arduino library

Photocell (Light Dependent Resistor) Library for Arduino

Sketchbook> GL5516>

- Download files from github.com/rkuo2000/arduino/examples/GL5516

- GL5516.ino

- LightDependentResistor.cpp

- LightDependentResistor.h

- Verify with NodeMCU-32S, and open Serial Monitor on ArduinoIDE

MQ Gas sensors

MQ2 300~10000ppm 煙幕感應器 (液化氧、丁烷、丙烷、甲烷、酒精、氫氣)

接線方式:VCC:接電源正極(5V)、GND:接電源負極、DO:TTL開關信號輸出、AO:模擬信號輸出

接線方式:VCC:接電源正極(5V)、GND:接電源負極、DO:TTL開關信號輸出、AO:模擬信號輸出

注意:感測器通電後,需要預熱20秒左右,測量的數據才穩定,感測器發熱屬於正常現象,因為內部有電熱絲,如果燙手就不正常了

MQ3 酒精蒸氣,乙醇,氣體檢測模組

- The typical sensitivity characteristics of the MQ-3 for several gases. in their: Temp: 20°C、 Humidity: 65%、 O2 concentration 21% RL=200kΩ

- Ro: sensor resistance at 0.4mg/L of Alcohol in the clean air.

- Rs:sensor resistance at various concentrations of gases.

MQ-135 空氣品質檢測 有害氣體感測器模組

用於建築物/辦公室的空氣質量控制設備,適用於檢測NH3,NOx,酒精,苯,煙,CO2等。

Sketch> MQ3>

- NodeMCU-32 GPIO36(A0) is connected to MQ3 sensor AO pin

|

|

-

MQ3 Vcc connected to 5V, required 15 minutes burn-in

-

Open Tools>Serial-Monitor>

-

Open Tools>Serial-Plotter> to see waveform

-

3 test cases: Fresh Air, Your Breathe, Marker are applied to MQ3 sensor

Electronic Nose

Detection of Fruits in Warehouse

Paper: Detection of fruits in warehouse using Electronic nose

Estimating Gas Concentration

Paper: Estimating Gas Concentration using Artificial Neural Network for Electronic Nose

This site was last updated June 18, 2023.